Discussion on the rapid detection method of textile color fastness and matters needing attention

1 introduction

Color fastness is one of the important indicators to measure the inherent quality of textiles. When the color fastness is not good, the dye will transfer from the textile to the human skin. Certain allergenic and carcinogenic dyes enter the body through the skin and may cause harm to the human body. At present, there are dozens of test items for the color fastness of textiles, including water resistance, acid and perspiration resistance, alkali perspiration resistance, dry rubbing resistance, saliva resistance, etc. The test volume is usually large, and the color fastness test needs to be tested. For the preparation of samples in various hues, it is often necessary to make multiple samples for multi-color fabrics. Therefore, in order to effectively reduce the number of samples or the number of repetitions due to invalid test results, this article combines a large amount of work experience to analyze and suggest the rapid color fastness test and the precautions in the process to improve the color fastness for the laboratory The detection efficiency provides technical reference.

2 Sampling and sample preparation

The color fastness test is mainly used to judge the fastness of the color of the sample. The color uniformity, pattern, fabric structure and other factors of the sample sampling site have a great influence on the rating result, so the sampling and sample preparation method is very important。

2.1 Plain fabric

For the plain fabric sample, select the part that is uniformly dyed, non-polluting, non-wrinkle, and representative of batch dyeing, so that the color change of the sample and the staining of the lining fabric are even. If it is a sample formed by splicing two or more plain-colored fabrics, select different color parts of the sample for testing. If it is insufficient, increase the sample amount or cancel the part of the test and indicate in the test report。

2.2 Multicolor fabric

Compared with plain fabrics, multi-color fabrics refer to fabrics containing two or more colors, such as printed fabrics, jacquard fabrics, and yarn-dyed fabrics. Due to the color fastness to water, acid and perspiration, and alkali and perspiration, two types of lining fabrics can be selected when preparing a combination sample, and the use of multi-fiber lining requires simultaneous evaluation of 7 component fabric staining and assessment requirements It is higher than the single-fiber lining, and when encountering samples with more patterns, each pattern must be in contact with different components of the multi-fiber lining, and more combined samples need to be made. The type of lining fabric also has a great influence on the color fastness rating results of textiles, and can even affect the judgment of whether the color fastness is qualified or not. Therefore, it is recommended to prefer single fiber lining fabrics to reduce the number of samples.

In the actual operation process, if the fiber content of the sample has been detected, the single fiber lining fabric is preferred to improve the efficiency when preparing the combined sample. If the sample composition and content are not provided, the composition is large, the test cycle is long, or the item is not tested, methods such as observing fabric characteristics and preliminary judgment of fiber composition can be used to select single fiber lining to make combined samples to reduce the number of samples. Shorten the overall sample detection cycle。

When selecting a single-fiber lining fabric, first observe the characteristics of the sample, combined with the state of the fiber close to the flame, contact with the flame, and when leaving the flame as described in FZ/T 01057.2-2007 "Textile Fiber Identification Test Method Part 2 Combustion Method" For the characteristics of the smell and residue after burning, burn the sample with a lighter, and preliminarily determine the fiber composition of the sample to select a single fiber lining fabric for testing. Since the color fastness test usually only needs the primary and secondary fiber components of the sample when selecting the single fiber lining, according to a lot of practical experience, the characteristics of some fabrics and the characteristics of burning are listed to provide a reference for judging the fiber composition of the fabric (see Table 1 ). If the fabric fiber composition is difficult to determine, use multi-fiber lining, preferentially cut relatively dark positions or take multiple sets of samples。

More anti-static information

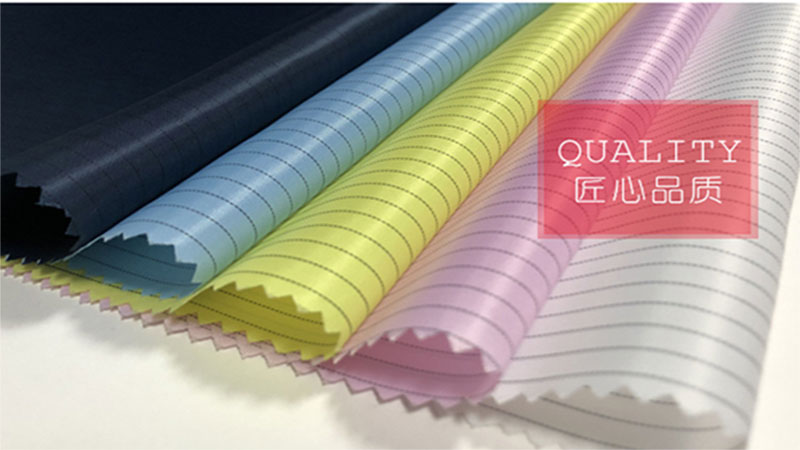

Design and development of antistatic clothing fabric

The design of antistatic clothing fabrics will be based on the antistatic performance requirements and organizational structure of the fabric. The content of organic conductive fibers in the fabric can reach different levels of antistatic effects when the content of the fabric is a few percent to a few ten thousandths. Therefore, conductive fibers It will not be used in "pure spinning", it must be reasonably mixed with other fibers according to the different requirements of anti-static degree, so that the conductive fibers are evenly distributed in the basic fabric. When the fabric is added with organic conductive fibers, filaments, fibers, slivers, etc. can be used Add by mixing.The content of conductive fiber yarn in the fabric is 11.5%, and the content of conductive fiber in the conductive fiber yarn is only 0.3%. It is necessary to ensure that the product has good antistatic performance. First, choose a reasonable cotton blending method to ensure uniform cotton blending and make The conductive fibers in the yarn are evenly distributed, and the yarn performance is stable. In addition, the use ratio of conductive yarn on the weft is the key to the design process. The different use ratio of conductive yarn on the weft directly affects the appearance and internal performance of the product, the style of the fabric and the conductivity The performance and size will change, so a reasonable blending method and appropriate use ratio are the key points for the development and production of new products. The method of mixing conductive fibers to produce antistatic yarns can eliminate electrostatic interference in the textile production process. The medium distribution is even, the antistatic effect is good and long-lasting. Under the premise of ensuring the uniform mixing of conductive fibers, other production processes are almost the same as those of general products, and the phenomenon of "entanglement, sticking, winding" in the spinning process is reduced.

Anti-static fabric

The anti-static fabric can prevent the accumulation of static electricity on the surface of the fabric, and the static electricity on the surface of the human body made of anti-static fabric can be quickly released. It not only solves the static electricity phenomenon in daily life, but also can be used in work clothes to play a role in special places to avoid safety accidents. Static electricity is dangerous to industrial production and warehouse storage. Static electricity itself can destroy sophisticated electronic instruments. Sparks generated by static electricity can ignite flammable and explosive materials. Therefore, in these areas that are sensitive to static electricity, work clothes made of anti-static fabrics should be used.